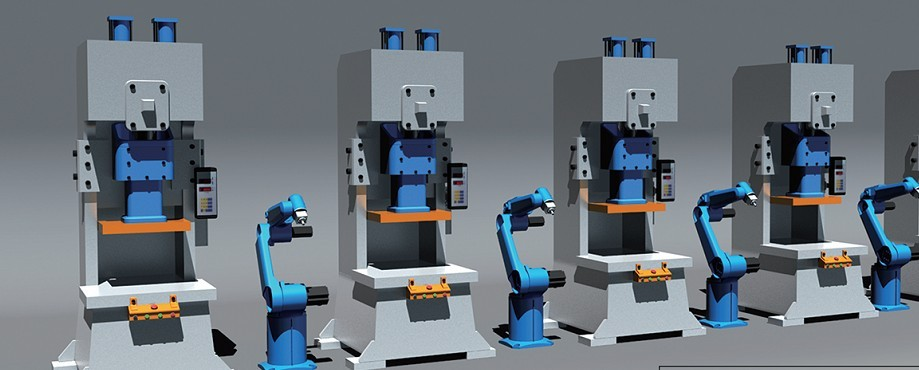

Application of intelligent punching manipulator

It can replace manual work and realize fast line change production mode.

After automatic production, production efficiency and delivery time can be accurately calculated, and are not affected by artificial uncertainties.

After automatic production, it can ensure the stability of product quality and reduce the defect rate.

The stamping robot operating unit can communicate and control each other with other peripheral equipment, which can realize the flexible demand of small and diverse production.

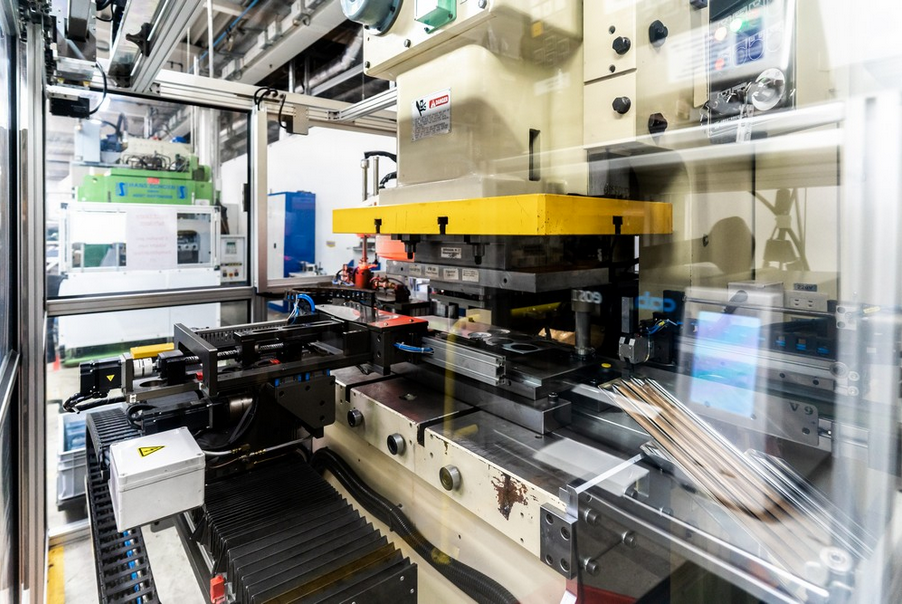

It is mostly used in electronics, digital, OA, home appliances, automobiles and other products, with high production efficiency, high safety performance, high material utilization, and high mold requirements and costs. Combined with the use of servo motors, it can meet the requirements of production efficiency and high precision at the same time. At present, the highest level in the market is: full automation of the whole process, and a variety of combination methods can better meet the higher requirements for products in the future.

At present, although the investment in the traditional manual production line is relatively small at the initial stage of construction, with the expansion of market demand, rising labor costs, poor product quality stability and other shortcomings, the development of enterprises is increasingly affected. Automatic production line can just solve these problems. Higher production efficiency, stable product quality and more optimized single piece production cost under the condition of large-scale production are the advantages of automatic stamping production line, especially for the production of various types of stamping products. The transformation and upgrading of intelligent manufacturing and automatic production have become the trend of the industry.